Extras

Things

like the router mount, the work surface, dust collection, and Estop and Home Switches. Topics that aren't covered

anywhere else.

The Router Mount

I

was originally planning on buying a mount for the Bosch Colt trim

router that I bought for this project. There are at least two sources,

Probotix sell a a mount for the V90 and MCPI also sells a

mount. However a friend posted .dxf

drawings for one on the Fireball CNC yahoo group site, based

on reading the BritishIdeas Blog. (Scroll down to the Rigid 2400 entry). I

thought I'd try my hand at making my own first.

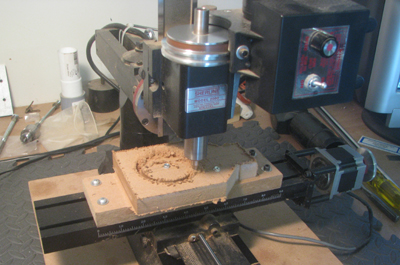

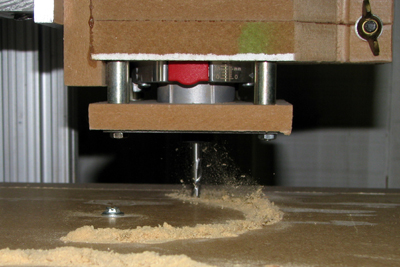

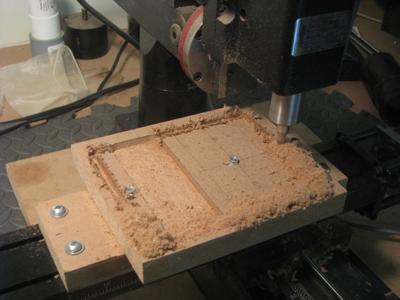

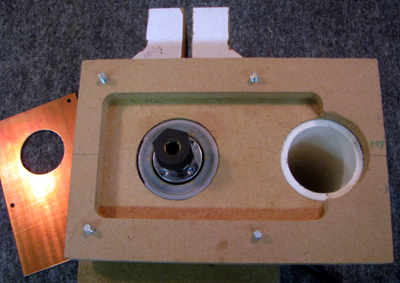

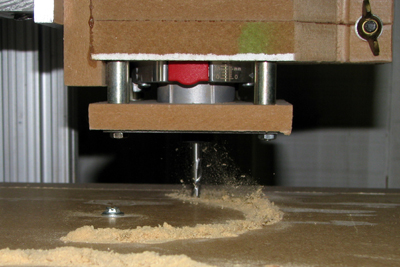

Here the outer edges of the raw blank have already

been machined away

and I'm cutting the mounting hole for the router. Note the screw that's

holding down the center part of the circle to keep it from coming loose

at the end of the cut. |

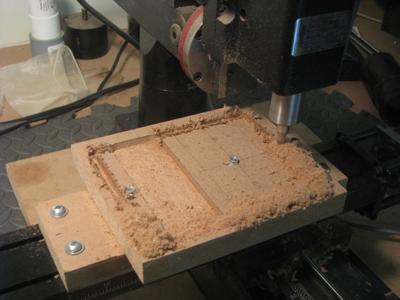

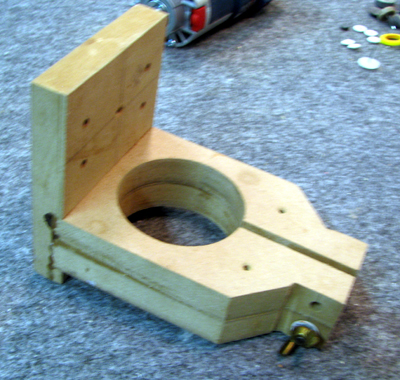

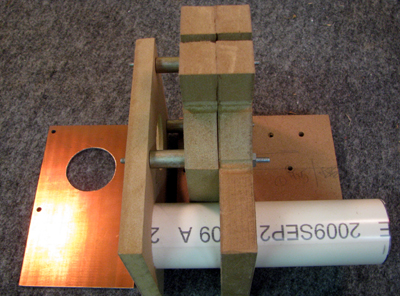

This

is the back of the mount. The part that you bolt to the Z axis plate.

The pocket has already been cut and the outer edges are being trimmed

off. |

|

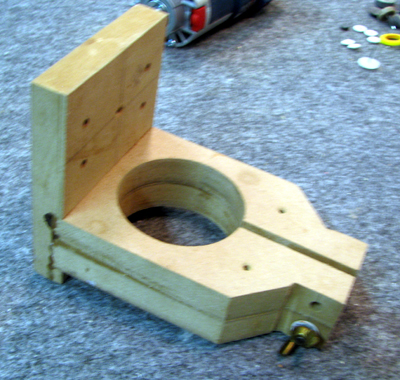

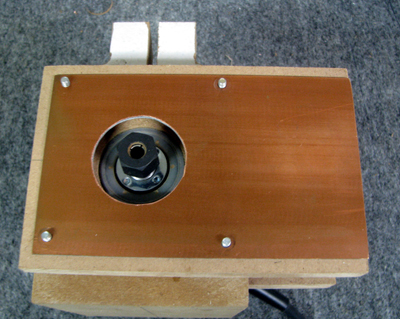

Here is the

mount glued together. You

can see it with the router installed in the assembly section. Consider

this as version 1. Based on some postings on the fireball cnc forum and

my limited experience using the router I'm

going to have to add a dust collection fixture to the mount.

See the entry below on Dust Collection for a

revised version of this mount!

|

Gotcha's:

(1) I had to cut two pieces for the part of the mount

that

holds the Colt. I'm cutting the first one in the picture above. Note

the machining order. I trimmed the outside first, then I cut the

circular part free and cut the slot between the 'jaws' of the mount.

Those were two separate gcode files. I made the mistake of

reversing the cutting order when I cut the second piece. The

circle & slot gcode was already loaded so I figured why not. I

must

have been tired. Really tired. The effect of cutting the circle is to

remove the anchor from the left end of the piece of stock. There's

nothing holding it down when you go to do the trim cut. That's 3/4 inch

MDF and it's amazing how much it can flex!

(2)

Glue the two jaws together before you cut the back of the mount. That

way you can make sure that they fit into the slot you are cutting in

the back piece.

The Work Surface

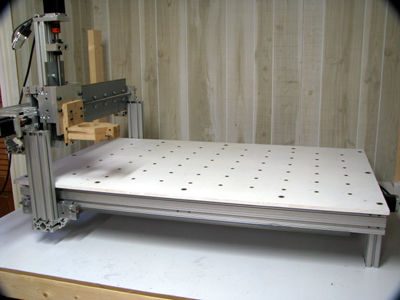

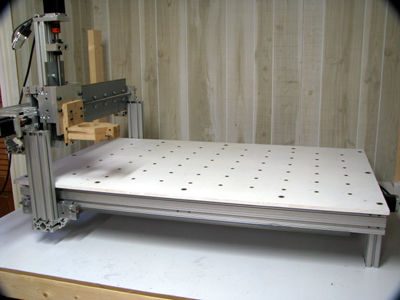

CNC

routers wind up with lots of work surfaces stacked one on top of the

other. At the bottom of the heap is the nice sturdy, stable, heavy duty

one that you really don't want to cut into. On top of it are a variety

of work holding fixtures and sacrificial surfaces that allow you to cut

all the way thru the work piece without damaging the real work surface

underneath. This accumulation of surfaces is a

double edged

sword. The closer you can bring your work piece to the bottom of the

router the better. Closer means there will be less flexing and better

accuracy. But eating up too much space means the size of the workpiece

will be restricted.

Folks

have used lots of material for their work surfaces. MDF is typical but

I've seen aluminum plate, 80/20 extrusions and corian among the choices

folks have made. I decided on MDF as the low cost option, figuring I

could upgrade later on if it proved to be inadequate. Two

posts, from the fireballcnc forum, prompted my choices of the

worksurface design. Table Flatness

convinced me that I should use two layers of MDF. T-Nuts

is a good explanation of how to use them and convinced me that they

would be a better alternative than insert nuts. Based on those two

posts, I decided on a work surface using two sheets of 1/2" MDF.

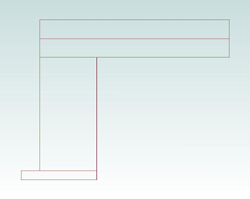

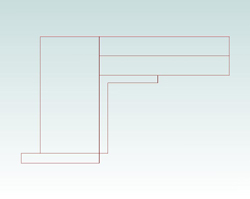

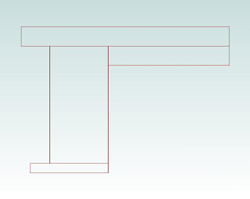

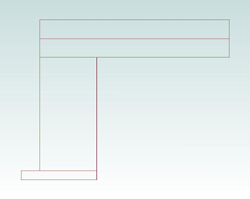

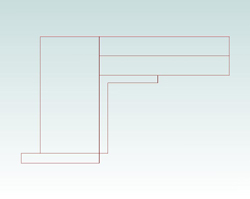

I came up with three options for mounting the work surface.

1 - The conventional mounting |

2 - Using an angle bracket to save working height |

3 - Recessed bottom layer with extended top |

The conventional mount would cost 1 inch of working height.

The Angle bracket mount would save that height at the expense of

additional parts and a more complicated alignment for the top.

Recessing the bottom layer saves 1/2 inch with no added expense.

Extending the top over the base rail shields the rail from some of the

dust and debris generated by the router. I used the third option

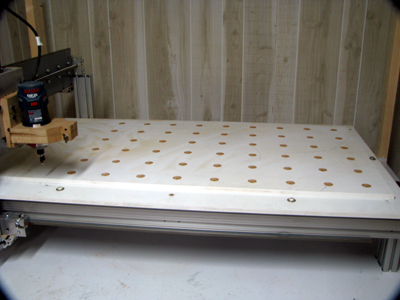

The router was used to 'drill' the bolt holes in the top. |

And then a V bit was used to countersink the bolt heads |

The recessed layer was then drilled and spot faced |

And the Tee Nuts were installed |

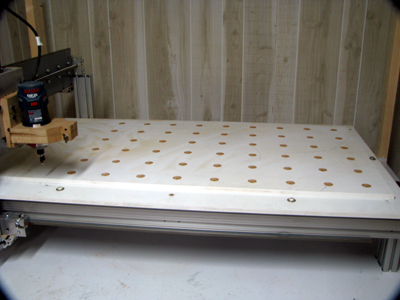

The finished work surface.

The mounting holes around the edges were also countersunk

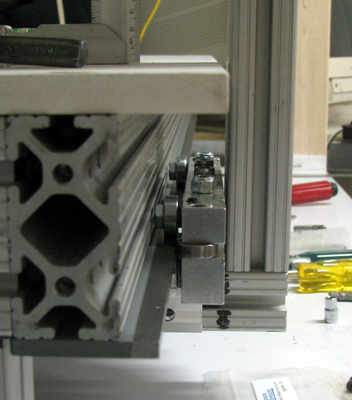

Right: The work surface overhangs the bearings to protect

them from debris |  |

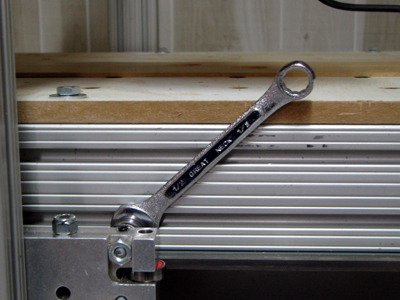

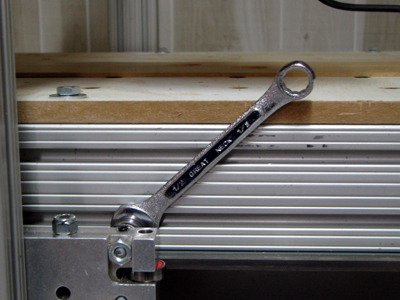

So, It turns out that it's a really Bad Idea

to have the work surface overhang table. While it can protect the

bearings from dust, It also makes it impossible to get a wrench in if

you have to adjust the carriage. I wound up removing the top and

cutting off the overhang.

To the right you can see the modified work surface with a wrench in place for carriage adjustments. |  |

Dust Collection

The

first thing I used my new router mount for was to cut the holes in the

work surface for the tee nuts. Dust and chips from the MDF got

everywhere even though I was holding a vacuum intake hose right next to

the router bit. I

remembered a post in the Fireball CNC forum "Dust

Revisited".

The downdraft from the router cooling air was blowing the dust away

before the vacuum could suck it up. Using the idea's there I

re-designed the Bosch Colt mount (above) and added a

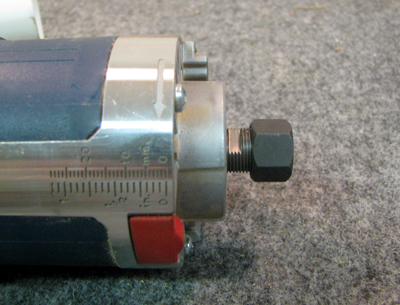

combination exhaust deflector and dust collector/vacuum boot.

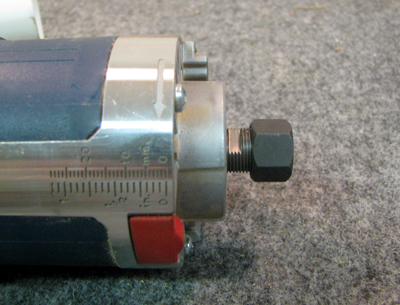

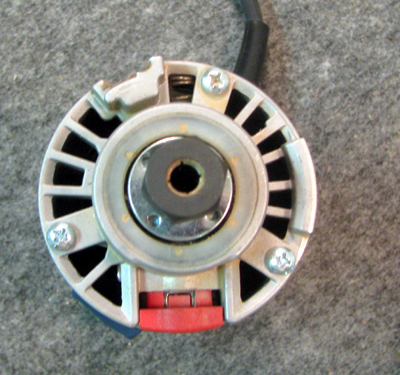

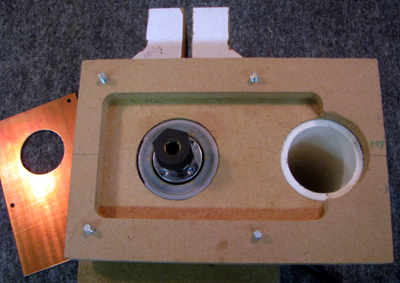

This is the Business end of the Colt Router.

Because of the uneven profile, there's no convenient place to mount a downdraft deflector |  |

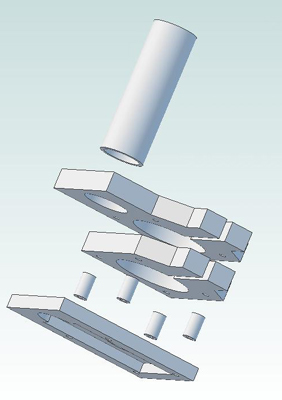

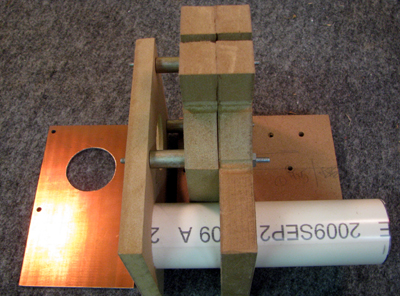

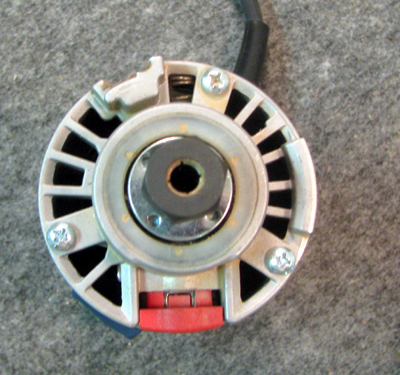

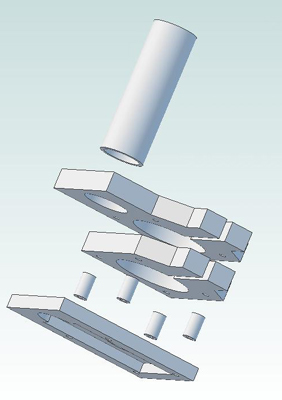

| I modified the original Bosch Colt mount by attaching a combination downdraft deflector and vacuum

intake to the original mount. Not shown are four pieces of threaded rod

that hold the assembly together (see below). The spacers are 7/8 inch,

designed to leave enough space to fit a finger into the mount to engage

the spindle lock when changing bits.

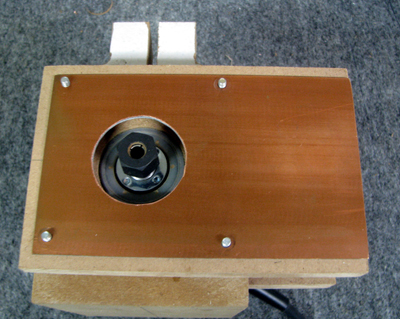

The bottom is sealed with a thin sheet. I was going to use some plastic

but didn't have any so I cut a piece of printed circuit board laminate

that I had handy.

You can look at a 3D PDF model of the mount.

You can download .dwg and .dxf files for the version 2 mount. |

The Colt is a tight fit into the hole in the dust catcher. |  |

|

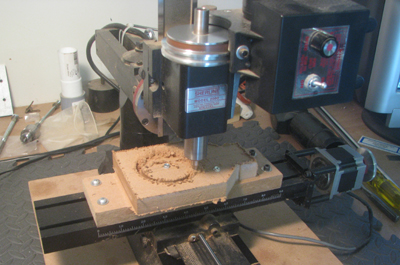

This

pix was taken during my first test cut. notice the tornado of dust

flying up into the intake. Yes some was left behind on the work surface

but at least it stayed put. It was mostly in the slot that was being

cut and was easy enough to vacuum up when the cut was over. |

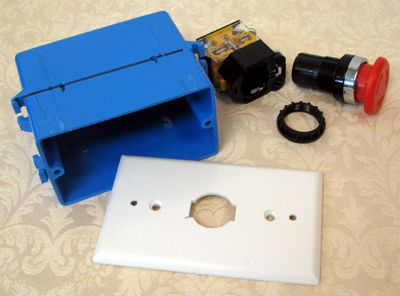

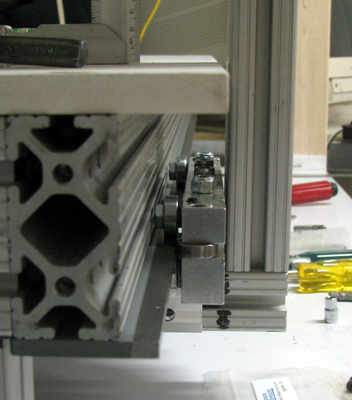

eStop and Home

Switches

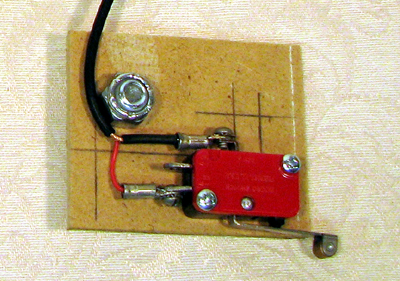

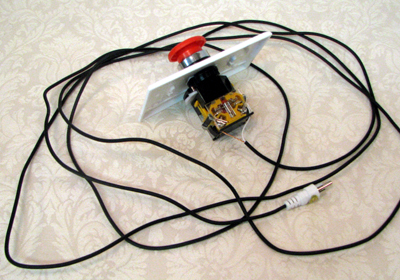

I

went on-line to find a source for an inexpensive eStop switch.

Experience with my Sherline 2000 mill has shown me that I'm not fast

enough going to use my keyboard to stop the mill when there's a

problem.

When I found a source for the eStop switch I also found a supplier for

home/limit switches so I bought some to use on this router as well. Figuring

out how to mount them was a little bit of a challenge. It's important

that the switch not be damaged by overtravel. Sometimes it's

convenient to be able to move the carriage beyond the switch without

having to remove the switches.

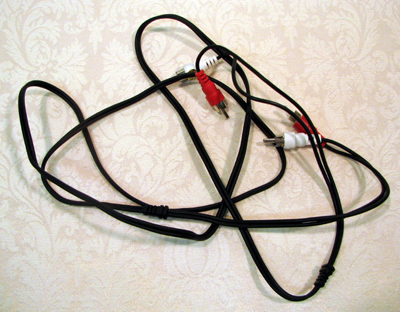

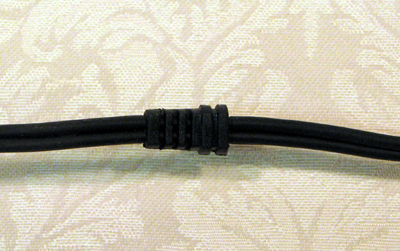

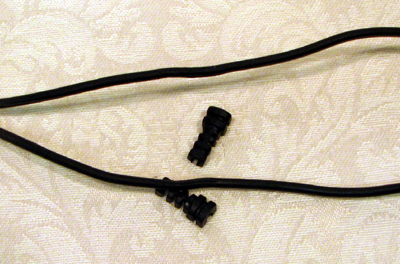

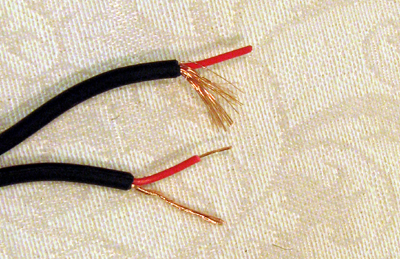

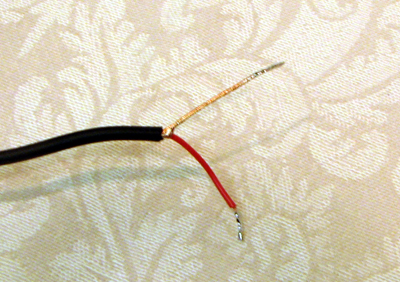

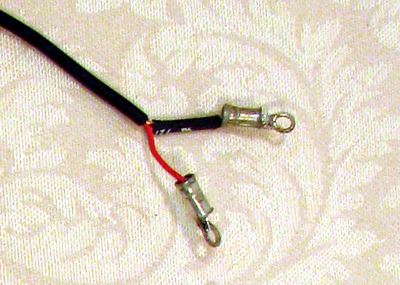

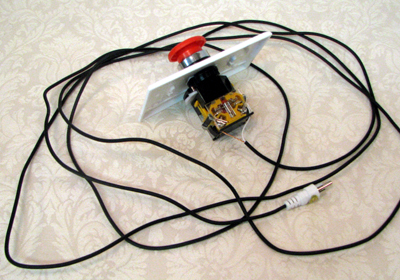

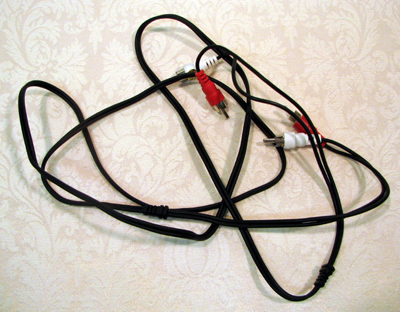

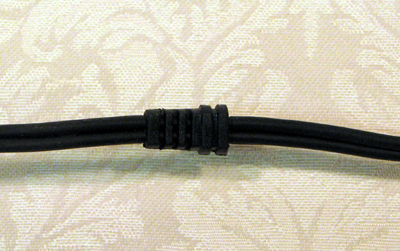

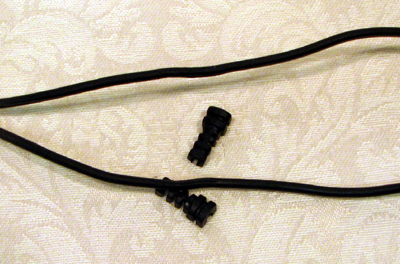

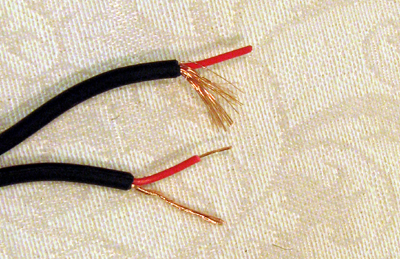

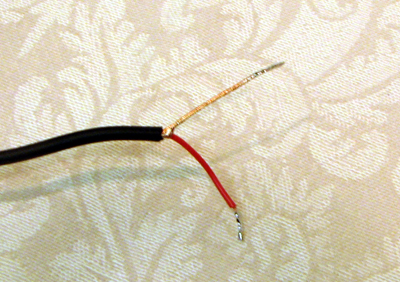

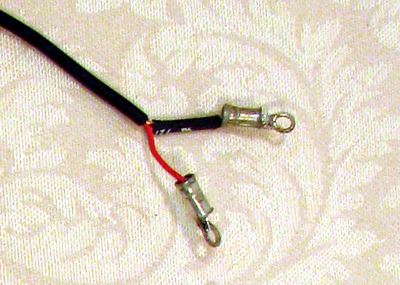

For

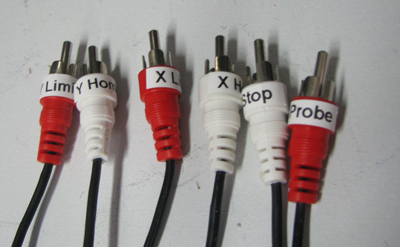

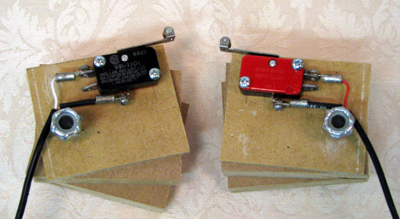

the home switch and eStop switch wiring I used stereo audio cables

with RCA phono plugs. These mate with the connectors I used on the

electronics enclosure. They are cheap, and the stereo pair is easy to

separate into single cables. I put terminal lugs on the ends of the

cables I used on the limit switches with shrink insulation on the bare

ground wire since it's close to the other switch contact.

|  |

|  |

|  |

|  |

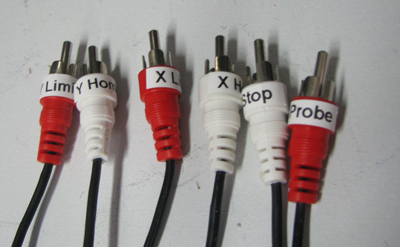

| Make sure you label the ends of the limit switch cables. |

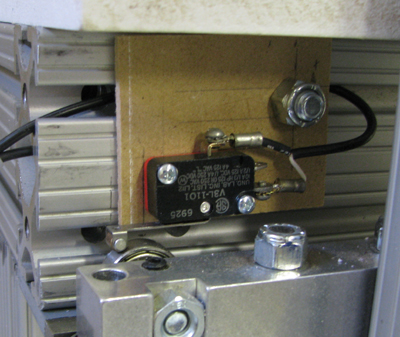

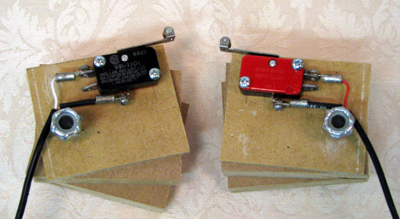

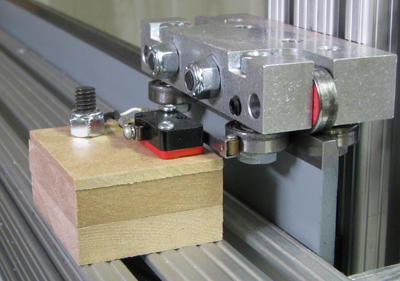

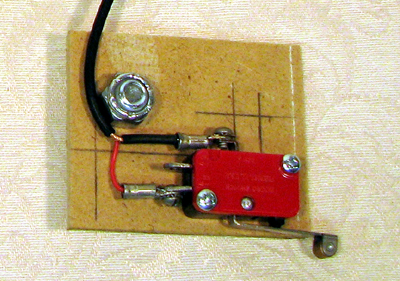

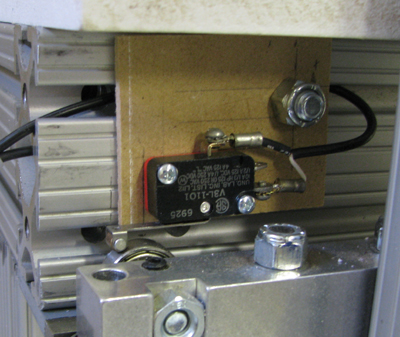

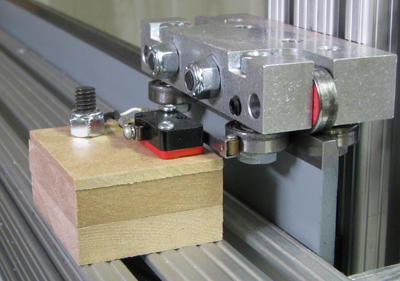

The Home switches were easier to mount than I had originally expected. I made a small mounting

plate out of 1/8 inch thick paneling and them bolted the plate in place

using the same type of carriage bolts that are used througout the

router build. This worked easily for the X-axis. In order to use the

same mounting technique for the Y-axis I made 1 inch spacer blocks to

position the switches correctly. You can download .dwg and .dxf files

for the switch mounting plate. The switches are Micro Switch V3L-1101

series. A .pdf data sheet is included with the mounting plate drawings.

|  |

|

I have since moved this switch to the underside of the beam

Where it's more out of the way. |

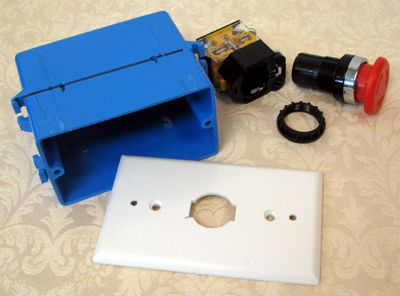

The

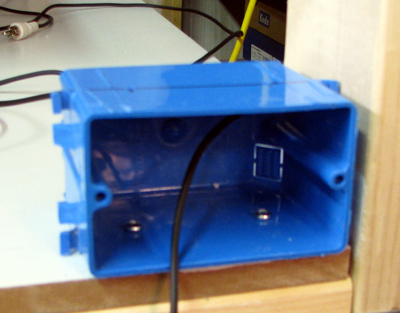

eStop switch is mounted on a standard switch cover plate and then

installed in a standard outlet box. There are a wide variety of

switches on the market. This one, purchased on eBay, appears to be

chinese in manufacture see the Jiangyin Changjiang Electronic Appliance Co. web site.

The only markings I could find were LA23/203/209B. It mounts in a

22.5mm hole and the mushroom top is 38mm in diameter. A really nice

switch for the price! The cover plate drawing is included with the micro switch mounting files above.

|

I used the same kind of audio cable with RCA phono

plugs as with the limit switches |

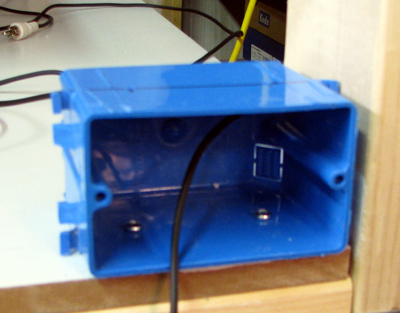

| Holes were drilled in the sides of the outlet box for

mounting. The cover plate is oversized and hides

the nail mounting flanges on the ends of the box. |